In the world of modern manufacturing, precision, efficiency, and cost-effectiveness are key factors that determine the success of any production process. Among the many advanced manufacturing techniques available today, Metal Injection Molding (MIM) has emerged as a game-changer. MIM Parts are now widely used across various industries, from automotive and aerospace to electronics and medical devices. This article presents a detailed comparison between MIM Parts and traditional manufacturing methods, exploring their processes, advantages, limitations, and applications.

Understanding Metal Injection Molding (MIM)

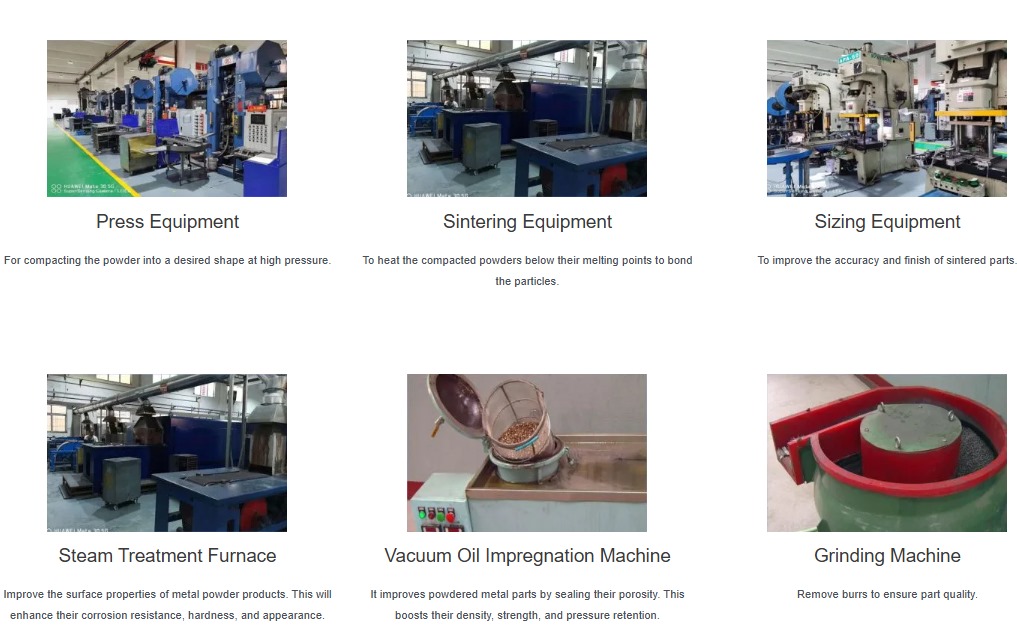

Metal Injection Molding is a manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of metal. The process begins by mixing fine metal powders with a thermoplastic binder to form a feedstock. This feedstock is then injected into a mold cavity, creating a desired shape. After molding, the binder is removed through a debinding process, and the remaining metal structure is sintered at high temperatures to achieve its final strength and density.

MIM technology enables manufacturers to produce complex, high-strength metal components with excellent precision and surface finish. MIM Parts are especially beneficial for applications that require small, intricate shapes and consistent performance.

Overview of Traditional Manufacturing Methods

Traditional manufacturing encompasses processes such as machining, casting, forging, and stamping. Each method has been used for decades and remains important in industrial production.

- Machining: Involves removing material from a solid block of metal using cutting tools to achieve the desired shape.

- Casting: Entails pouring molten metal into a mold to form a part that solidifies upon cooling.

- Forging: Uses compressive forces to shape metal into the desired form, improving strength and durability.

- Stamping: Involves pressing or punching metal sheets into shape using dies and presses.

These traditional methods are well-established and offer reliable results, but they often struggle with producing highly intricate geometries at a reasonable cost and speed.

Process Comparison: MIM vs. Traditional Methods

Design Complexity

MIM Parts allow for exceptional design freedom. Because the process relies on injection molding, it can produce complex geometries with internal cavities, undercuts, and fine features that would be difficult or impossible to achieve through machining or forging. Traditional methods, in contrast, typically require multiple machining steps or assembly of several components to create similar complexity.

Material Utilization

MIM offers superior material efficiency. Since it uses a powdered metal feedstock, there is minimal waste compared to machining, where excess material is removed and discarded. This makes MIM an environmentally friendly and cost-effective option, particularly for high-volume production.

Production Volume

Traditional machining and forging are ideal for low to medium production volumes, where setup costs are relatively low and flexibility is high. MIM, however, excels in high-volume manufacturing. Once the mold is designed and produced, thousands or even millions of MIM Parts can be created with consistent quality and reduced per-unit cost.

Dimensional Accuracy

MIM Parts are known for their excellent dimensional precision, often achieving tolerances comparable to or better than those of traditional methods. The sintering process used in MIM ensures minimal distortion and high density, leading to parts with tight tolerances and smooth surfaces. Machined parts can also achieve high precision, but they often require multiple finishing steps that add to the cost and time.

Surface Finish

MIM components typically exhibit a fine surface finish right out of the mold, requiring little to no post-processing. Traditional manufacturing, on the other hand, may need polishing, grinding, or coating to achieve a similar finish.

Cost Analysis

Cost plays a crucial role in deciding between MIM and traditional manufacturing.

- Tooling Costs: MIM requires specialized molds, which can be expensive to produce. However, once the mold is made, the cost per part decreases dramatically with higher volumes. In contrast, machining and forging have lower initial setup costs but higher per-part expenses due to labor and material waste.

- Material Costs: MIM uses fine metal powders, which can be more expensive than bulk materials. Yet, the reduced waste and higher material utilization often balance this difference.

- Production Efficiency: For complex parts produced in large quantities, MIM offers significant cost savings compared to traditional methods. For low-volume or large simple parts, conventional techniques might remain more economical.

Mechanical Properties

MIM Parts are known for their high density—typically between 95% to 99% of wrought metal properties—making them suitable for structural and load-bearing applications. The sintering process results in a microstructure that closely resembles forged or cast metals.

Traditional methods such as forging still produce the strongest parts due to work hardening and directional grain flow. However, MIM has improved significantly over the years, and the mechanical properties of MIM Parts now meet or exceed the requirements for most industrial and consumer applications.

Environmental Impact

Sustainability is becoming increasingly important in manufacturing. MIM Parts have a distinct advantage due to minimal material waste and energy-efficient production. The binder removal and sintering stages are optimized for reduced emissions and energy consumption.

Traditional machining, in contrast, often generates substantial metal scrap and consumes more energy due to extensive cutting and finishing processes. Casting and forging also require high temperatures, leading to higher energy usage.

Applications of MIM Parts

The versatility of MIM technology makes it suitable for a wide range of industries:

- Automotive: Precision gears, turbocharger components, and safety system parts.

- Aerospace: Lightweight brackets, sensors, and structural components.

- Medical: Surgical instruments, orthodontic brackets, and implantable devices.

- Electronics: Connectors, housings, and miniature mechanical parts.

- Consumer Products: Watch cases, hardware, and high-end tools.

These industries value MIM Parts for their strength, compactness, and aesthetic quality, which are difficult to match through conventional methods.

Limitations of MIM

While MIM offers many benefits, it also has certain limitations:

- High Initial Tooling Cost: Creating molds can be expensive, making MIM less suitable for small production runs.

- Size Restrictions: MIM is best suited for small to medium-sized parts (typically under 100 grams).

- Material Limitations: Not all metals are easily processed through MIM, though advancements continue to expand material options.

Choosing Between MIM and Traditional Manufacturing

The choice between MIM Parts and traditional methods depends on several factors—design complexity, production volume, cost, and material requirements. For intricate components that require precision, consistency, and efficiency in high-volume production, MIM is the superior option. However, for larger, simpler, or low-volume parts, traditional manufacturing techniques may remain the preferred approach.

Conclusion

Metal Injection Molding has transformed the way industries produce high-performance metal components. MIM Parts deliver outstanding quality, dimensional accuracy, and strength while reducing waste and costs in large-scale production. Although traditional manufacturing continues to hold its ground in certain applications, MIM stands as a highly efficient and innovative alternative that bridges the gap between precision and productivity.